Thermosensitive energy saving systems with tailored solar reflecting/absorbing properties for construction structures – THERMOSOLAR

Home

Romanian National Authority for Scientific Research

CNDI–UEFISCDI, PN-II-PT-PCCA-2011-3

project number 3.2-1391

contract number 54 / 2012

Objectives

- Development of thermochromic systems of donor-accepting type having a hypsochromic transition in the 25-75°C range;

- Development of thermotropic systems of hydrogel type used in coating materials, for transparent-translucent transitions in the 25-75°C range;

- Study and finding of the encapsulation methods for all types of thermosensitive mixtures proposed (thermochromic dyes and thermotropic hydrogels);

- Development of thermosensitive film building materials for different types of construction structures, by appropriate choice of resin host matrices and other components of the thermosensitive coatings;

- Dissemination on large scale of scientific results of the project, products and obtained technologies promotion.

Estimate results

New products:

- Encapsulated thermochromic compositions and thermotropic hydrogels;

- Thermosensitive film building materials with thermochromic and/or thermotropic transition.

Technologies for obtaining:

- Thermochromic compositions of donor-accepting type;

- Thermotropic hydrogels;

- Encapsulation of thermosensitive systems (thermochromic and thermotropic);

- Thermosensitive film building materials.

Publications:

Articles (6), Patents (1), Communications (2), Posters (2)

Stages

Stage I – 2012

Documentation and thermochromic and thermotropic systems design – development of the experimental model

Stage II – 2013

Alternatives for obtaining thermochromic and thermotropic systems – development of the functional model

Stage III – 2014

Implementation of laboratory technologies for thermochromic systems –experimental model implementation

Stage IV – 2015

Implementation of laboratory technologies for thermotropic systems –experimental model implementation.

Stage V – 2016

Technical feasibility study. Demonstration of functionality and utility of thermosensitive systems. Pilot experimentation of the technology for obtaining of film building thermosensitive materials.

Partners

National Research and

Development Institute for Chemistry and Petrochemistry – ICECHIM

University Politehnica of

Bucharest, Faculty of Applied Chemistry and Materials Science

SC CHIMCOLOR SRL

About

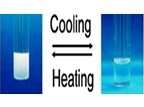

In principle thermochromic and thermotropic systems can function as energy saving systems. For high temperatures, during summertime thermochromic coatings have the ability to reflect solar energy, reducing the surface’s temperature; while in wintertime absorb solar energy, increasing the surface’s temperature as reversible color change takes place. Applied thus on external building surfaces, they have the potential for the reduction of heating and cooling loads, contributing to the reduction of urban temperatures, fight heat island and reduce air pollution. Color-changing compounds have become increasingly important in recent years in the study and the production of thermochromic coatings that is coatings which respond thermally to their environment, changing reversibly their color from darker to lighter tones as temperature rises.

The novelty comes from the use concomitant of thermotropic hydrogels which respond thermally by changing transparency from total transparent to translucent. Combining these features of termotropic hydrogels and thermochromic dyes we can obtain complex thermosensitive systems that respond to an increase in temperature by switching the color hypsochromically while accompanied by a change in transparency of the hydrogels. During the project we intend to develop thermosensitive energy saving coatings that action on the entire Vis-NIR range and are most typically applied to roofs but additionally can also be applied to exterior and interior walls in much the same way. Thermosensitive coatings that will aim to obtain change reflectivity

and color as a function of temperature, present enhanced weathering and durability and may be in any suitable formulation for application on roofs or

walls such as water-based, oil-based, epoxy-based or acrylic-based formulations.

Project development

Stage I – 2012

Documentation and design of thermochromic and thermotropic systems– development of the experimental model

At this stage of the project the following activities were carried out related to the plan of the project:

- synthesis of some color formers of triphenylmethane dyes type

- structurally accurate characterization of the compounds with the proposed structures

- study on the structural types of synthesized or commercially available color formers (structural features required for the use of thermochromic mixtures to be encapsulated)

- study regarding encapsulation of thermochromic mixtures, in dispersed aqueous medium, by miniemulsion polymerization, in the presence of monomer mixtures or inorganic polymers

- study of thermosensitive hydrogels obtained on the basis of cellulose derivatives (transparent-translucent transition temperature, gelation temperature and viscosity modification).

- structurally characterization of synthesized copolymers and their composition

- study on structural types identification and physico-chemical characterization methods regarding components necessary to obtain the thermosensitive materials

- obtaining and characterization of some film building matrices compatible with encapsulated thermochromic and thermotropic systems based on their fields of application. Research works have been accomplished by the following results:

· the experimental model of thermochromic compositions

· the experimental model of thermotropic hydrogels

· the experimental model of encapsulated thermochromic compositions

· film building matrices based on acrylic and epoxy resins

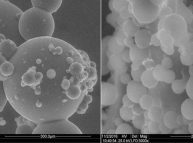

Dyes encapsulation in dispersed aqueous medium by miniemulsion polymerization was successfully achieved. To maintain the thermochromic effect

of dyes, different conditioning mixtures were chosen to carry out miniemulsion polymerization. Different latexes were obtained depending on the dye nature and conditioning additives. The use of the anionic and nonionic surfactants mixture provides the conditions to obtain stable latexes.

UPB obtained thermosensitive hydrogels based on cellulose derivatives and studied methods to change the transparent – opaque transition temperature and viscosity of the aqueous solutions. Hydrogels based on block-copolymers of PEG and PPG type and thermosensitive hydrogels based on

random copolymers were studied in order to establish the influence of the molecular weight of the polymer and the concentration of the aqueous solution,

the influence of alcohol, the addition of salts, surfactants and organic solvents on the behavior of the thermosensitive polymer.

CHIMCOLOR conducted activities related to the identification of structural types and methods of physico-chemical characterization of acrylic and epoxy matrices compatible with encapsulated thermochromic and thermotropic systems.

Stage II – 2013

Alternatives for obtaining thermochromic and thermotropic systems – development of the functional model

At this stage of the project the following activities were carried out related to the plan of the project:

- Effect of UV absorbers on the photofading of dyes in thermochromic systems

- Analysis of polymer matrix polarity effect on polymer dispersions containing thermochromic systems

- Establishing of analysis methods for the study of thermochromic systems in polymeric dispersions with different polarities

- Alternatives for obtaining of some encapsulated thermochromic systems

- Alternatives for preparing thermotropic systems of hydrogel-type, based on aqueous solutions of thermosensitive polymers

- Synthesis and characterization of thermosensitive polymer crosslinked microgels with the temperature of volume phase transition in the range 25-75°C

- Alternatives for obtaining of some thermosensitive film building materials

- Alternatives for obtaining of some thermochromic systems of donor-accepting type

Research works have been accomplished by the following results:

- The functional model to obtain a blue thermochromic composite material

- The functional model to encapsulate the blue thermochromic composite material

- The functional model for obtaining thermochromic flame retardant coatings

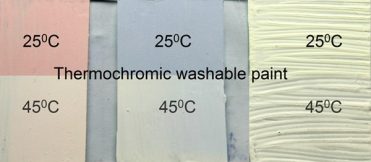

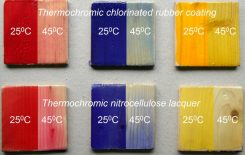

- The functional model for obtaining thermochromic nitrocellulose lacquers and washable film building materials

The study on the effect of several types of light stabilizers on the behavior of the thermochromic systems revealed the superiority of nickel quenchers over the classical UV absorbers and HALS without affecting essentially the thermochromic equilibrium the transition temperature or the contrast obtained. Regarding alternatives for color developers various biphenolic compounds were studied, including organic dyes containing phenolic groups, but the properties of the thermochromic mixtures were not remarkably improved.

Different systems used for encapsulation were obtained and analyzed in relationship with the effect of the polymeric matrix polarity on the dispersion stability and on the thermochromic behavior. As an alternative to the systems studied, were obtained encapsulated mixtures by interfacial polycondensation. In order to ensure a good dispersion of the organic phase in the aqueous phase, are used different polymeric alcohols, non-ionic surfactants and copolymers with more hydrophilic monomers.

The partner UPB conducted experiments in order to obtain different thermotropic systems based on polymers of N-isopropylacrylamide and N-vinylcaprolactam and copolymers with monomers more hydrophilic (acrylamide, acrylic acid) or more hydrophobic (N-t-butylacrylamide). The influence of different additives to the aqueous solutions of these polymers was studied with respect to the transition temperature. The study was completed with a series of cross-linked thermosensitive polymer microgels using different bifunctional monomers as cross-linking agents.

Partner CHIMCOLOR conducted activities related to the identification, selection and physical-chemical characterization of the components necessary for the thermosensitive coating materials. Thus, during the experiments were obtained and characterized film building matrices based on: chlorinated rubber, nitrocellulose or hydroxyethylcellulose. Also, were carried out tests to obtain thermochromic coating materials by incorporating blue, red and yellow encapsulated thermochromic mixtures in the selected film building materials.

Stage III – 2014

Implementation of laboratory technologies for thermochromic systems –experimental model implementation

In the third stage of the project, the three partners conducted activities related to a comparative analysis of the systems studied, their properties evaluation, selection and characterization of the systems with transition temperature in the range 25-750C, respectively the production technologies for thermochromic systems, and their encapsulation in order to obtain thermochromic coatings materials.

The project leader INCDCP – ICECHIM carried out activities related to the assessment of physico-chemical and transition properties of thermosensitive materials, selection and characterization of the systems showing a hypsochromic transition in the range 25-750C and the development of their manufacturing technology. As was shown during other research stages, thermochromic compositions considered for obtaining film-forming materials must meet three important requirements, namely: achieving optimal contrast between the two states (before and after the transition), optimal capacity transition to thermal stimuli and high stability of the color obtained to light and weathering. Of particular importance is the selection of those compositions which have a hypsochromic transition to the temperature elevation, for reasons related to the reducing of heat absorption when the outdoor temperature increases. The reversibility of the process must be maintained over many heating – cooling cycles as the outdoor temperature could be significantly above or below the transition temperature.

The main components of the thermochromic compositions established during investigations are: the color former, the color developing agent and solvent of the thermochromic mixture. During investigations were selected triphenylmethane lactones as color formers and various bisphenols as color developers, while C12-C16 fatty alcohols and fatty acid esters of polyhydric alcohols, and mixtures thereof were selected as solvents. It should be noted that the solvent determine the transition temperature regardless of the nature and quantity of the other components in the mixture. The selected systems present hypsochromic transitions in the range 25-750C are made of Crystal Violet Lactone and its derivatives together with bisphenols, in fatty alcohols or fatty acid esters for transition temperatures above 500C. The molar ratios established as optimal for all thermochromic mixtures were determined by the JOB method, from both the absorption/reflective spectra and from fluorescence emission.

The data obtained by optical methods lead to the establishment of optimal ratio between components and it was verified by calorimetric measurements. For all optimal compositions were selected additives used as light stabilizers and the manufacturing technology of thermochromic mixtures with transition temperature in the range 25-750C has been carried out.

With regard to encapsulation of the thermochromic compositions, have been tried many options for both compositions comprising fatty alcohols and esters, by establishing the optimal systems of melamine-formaldehyde and urea-formaldehyde resins. The main reason is due to the very weak interactions between polymers obtained and composition, which does not affect the thermochromic equilibrium and color of the compositions obtained. The capsules obtained by these variants retain systems integrity, providing a shell that resists well to mechanical stress without breaking and which does not allow interactions of the core with the external environment.

Encapsulation technology determined to be optimal comprises the following steps: polycondensation reaction of melamine with formaldehyde,

stabilizing the melamine-formaldehyde resin, obtaining of the final solution of encapsulation, melting and mixing the thermochromic complex with the pre-formed resin solution, neutralizing the pre-formed resin solution to provide an aqueous dispersion of encapsulated thermochromic microcapsules and isolating the particles by centrifugation, filtration, washing and drying.

The main tasks carried out by the UPB partner within the year 2014 were as follows: a) comparative analysis of the thermotropic systems studied and b) selection and detailed characterization of the best systems with the transition in the 25-75°C range from the point of view of performance and application.

The thermotropic systems developed during the 2012-2013 phases were compared from the point of view of the transparent-opaque transition temperature, stability, degree of opacity, resistance to freezing and commercial availability/price of the polymer. It resulted that the most

promising thermotropic systems are those based on a) Pluronic L31, especially because it is a cheap and commercially available polymer (industrial product), and forms systems with acceptable properties and b) N-isopropylacrylamide – acrylic acid copolymer, due to the formation of solutions with a high level of opacity (increased degree of whiteness) and good stability, even in the presence of co-solvents which ensure a good resistance to freezing. The systems with the best properties, i.e. those based on Pluronic L31 and NIPAM-AAc copolymer, selected within the Task III.1, were subjected to additional investigations consisting in the examination of the behavior of the aqueous solutions of these polymers in the presence of additives/co-solvents mixtures, others than those already employed during the 2012-2013 phases. The systems studied in the case of Pluronic L31 consisted in 5 wt.-% polymer dissolved in aqueous solutions containing the following mixtures as additives: a) DMF-DMSO; b) DMF – ethylene

glycol (EG); c) dioxane – EG; d) 1,2-propyleneglycol (PG)-DMSO; e) dioxane –nBuOH; g) DMF – nBuOF; h)PG 20%- EG 20% – surfactant (SDS or Tergitol NP-9). In the case of NIPAM-AAc copolymer, the properties of the 1 wt.% polymer solutions with the following additives: a) dioxane -DMSO; b) dioxane – nBuOH; c) dioxane – EG; d) dioxane – PG; e) DMF – surfactants (SDS, Tergitol NP-9); f) dioxane – Tergitol NP-9; g) PG – SDS, were studied.

At this stage CHIMCOLOR partner carried out activities related to the assessment of physico-chemical and transition properties of thermosensitive materials by performing tests on the behavior of the microcapsules in the field of forces in atritors used to obtain coatings materials. The fastness properties, color, and integrity of the film-forming materials were tested for various substrates and in correlation with the

response to thermal excitation and reversibility of the thermochromic process in successive cycles of heating and cooling. In this step has been accomplished the obtaining technology of thermochromic film-building materials with hypsochromic transition in the range 25-750C for three primary colors (red, yellow and blue) and three types of film-forming materials.

Stage IV – 2015

Implementation of laboratory technologies for thermotropic systems–experimental model implementation.

In the fourth stage of the project, the three partners have carried out activities related on alternatives for obtaining encapsulated thermotropic systems of hydrogel-type, physical-chemical characterization of thermochromic systems obtained in an earlier stage of the project, obtaining laboratory technology for thermotropic systems with transition in the 25-75°C range, assessing physical-chemical, mechanical and transition properties of thermosensitive film forming materials, selection and characterization of thermotropic coatings which shows the transition in the 25-75°C range.

The project leader – ICECHIM by the research team specialized in dyes chemistry, conducted activities related to physico-chemical characterization of the thermochromic systems developed in a preceding stage, as well as evaluating of the thermochromic film forming materials transition properties. Regarding thermochromic compositions previously studied it was considered the fact that embedding in film-forming materials can bring changes in the behavior of thermochromic systems depending on interactions that can occur between components, characteristics of the material used for encapsulation or presence of certain species in the film-forming material, the type of solvent used, etc. As a rule, in order to obtain thermochromic coating materials, there are three important requirements, namely: achieving optimal contrast between the two states (before and after the transition), optimal sensitivity to the appearance of a temperature difference and high stability to light and weathering of the colors obtained. Physico-chemical characterization of thermochromic systems includes recording of reflectance spectra and color measurements in dynamic conditions as a function of the temperature both on thermochromic mixtures and on compositions encapsulated in melamine-formaldehyde resins – set in an earlier stage as optimally materials for the encapsulation process. Hypsocromic systems with transitions between 25-75°C are formed by Crystal Violet Lactone and derivatives thereof together with phenols, fatty alcohols, fatty acid esters and mixtures thereof. On the basis of the spectral reflectance, fluorescence data or thermal analysis, it was determined the optimum molar ratio between the phenolic component and the dye, and from the maximum absorbance reached, while maintaining the characteristics of the thermochromic optimum range of temperature, it was determined the optimum concentration of the dye in the mixture. Thus, it was established an optimal molar ratio dye-polyphenol situated in the range 1:1-1:4 depending on the components and a maximum concentration of the dye in the thermochromic mixture of 20% by weight.

Regarding thermochromic mixtures encapsulated in melamine-formaldehyde resins, particle size distribution was determined by DLS in aqueous dispersion, emphasizing for all encapsulated mixtures an asymmetric distribution situated around 5-6 μm. Differential thermal analysis reveals very high thermal stability of the thermochromic capsules up to 200°C and the presence of thermal effects proper to solvent and co-solvent present in the thermochromic mixture. The study of alternatives for obtaining thermotropic embedded systems and selection of thermotropic embedded systems was the subject of one of the activities developed by the team specialized in polymeric materials within ICECHIM. In order to microencapsulate thermotropic aqueous systems, it is imperative that in terms of forming a protective layer to use materials that present an initial interaction with the aqueous core and a good dispersibility in the solvent used to prepare the initial dispersions.

A variant for encapsulation was to create a shell by sol-gel processes in both acidic and basic media. As precursors for sol-gel processes were used different alkoxysilanes and as surfactants were used oleic acid derivatives. Also, it was studied retention of water belonging to the initial phase of preparation after the organic solvent is removed. In good agreement with previously published data, after removal of the solvent most of the water evaporates due to the porous structure of the silica.

An option for obtaining a protective layer was the anionic polymerization of cyanobutylacrylate (BCA). Making an external shell of PBCA was carried out by “in-situ” polymerization in the presence of water containing thermosensitive polymer. Thus, some microemulsions prepared by UPB were modified by BCA polymerization at water-solvent interface.

The main task carried out by the UPB partner within the year 2015 was as follows: Elaboration of the technology for the synthesis of the thermotropic systems with the transition in the 25-75°C range.

A technology for the synthesis of the N-isopropylacrylamide – acrylic acid copolymer with 10 mole-% acrylic acid was elaborated. This copolymer has been proven within the research works carried out within the project during the previous years as being the most promising from the point of view of the transparent – opaque transitions in aqueous solution triggered by temperature variations. The intention was that the final product of this technology be the aqueous solution, which can be further used, as such or diluted, within the encapsulation process. With this aim in view, the copolymerization of the two co-monomers was carried out in demineralised water as the solvent, at 24 – 26°C, under nitrogen atmosphere, by employing the potassium persulfate – potassium metabisulfite redox initiating system. The total weight concentration of the two co-monomers in solution was 5%, while the reaction time was 24 hours. The overall monomer conversion was over 98%. The main steps of the technological process are the following: the acrylic acid distillation in order to remove the inhibitor; the preparation and degassing of the aqueous solution of monomers and potassium metabisulfite; preparation and degassing of the aqueous solution of potassium persulfate; the polymerization; packing of the polymer aqueous solution. A mass balance was carried out for each technological step, and then the overall mass balance.

At this stage CHIMCOLOR conducted activities related to the assessment of physical-chemical and transition properties of thermosensitive film forming materials by testing coatings on the behavior of the materials to environmental factors and natural and artificial light. Also, there were tested their fastness properties, color and coating materials integrity on various substrates correlated with response to thermal excitation and reversible process during successive cycles of heating and cooling for both aqueous varnishes, and lacquers selecting optimal products.

Stage V – 2016

Technical feasibility study. Demonstration of functionality and utility of thermosensitive systems. Pilot experimentation of the technology for obtaining of film building thermosensitive materials.

The project leader ICECHIM by the team specialized in dyes chemistry conducted activities related to experimentation technology of thermochromic systems with transition in the range 25-75°C, in order to verify the technology reproducibility and to achieve the required amount of thermochromic complex which after encapsulation will be used in pilot testing of thermochromic coatings. Experiments were conducted in laboratory conditions in order to optimize the encapsulation of the thermochromic systems in water-insoluble polymer shells of melamine-formaldehyde resins by varying the parameters of the synthesis and increasing the efficiency of encapsulation.

The optimized technology comprises the following steps: polycondensation of melamine with formaldehyde and prepolymer stabilization; thermochromic complex emulsification and stabilization; the encapsulation of the thermochromic complex; crosslinking of the shell; filtration, washing and drying of the thermochromic capsules. Verification of the technology reproducibility was made by obtaining several batches of different microencapsulated thermochromic complexes with different transition temperatures.

The main task carried out by the UPB partner was the technology experimentation for the synthesis of the thermotropic systems with the transition in the 25-75°C range.

In the first step the solution for some deficiencies of the technology elaborated during the year 2015 was looked for. These deficiencies were: a relatively high viscosity of the N-isopropylacrylamide-acrylic acid copolymer aqueous solution; agglomeration of the polymer from the aqueous

solution after a few transparent-opaque cycles (20°C-50°C). In the first case the best results were obtained by adding isopropanol as the chain transfer agent in the reaction medium in order to decrease the molecular weight of the copolymer. In the second case the solution was the employment of the hydrogen peroxide-ascorbic acid redox initiating system. The proposed technological process was then experimented at a larger scale (about 1 Kg), by employing experimental conditions as close as possible to the industrial ones, including unpurified monomers. The main steps of the technological process are the following:preparation and degassing of the water/isopropanol solution of monomers and ascorbic acid; degassing of the aqueous solution of hydrogen peroxide;polymerization;packing of the polymer aqueous solution.

The final concentration of the polymer solution was 5%, while the overall conversion of monomers was over 98%. The copolymerization process was carried out under inert atmosphere at 20-25°C for 20 hours. A mass balance was carried out for each technological step, and then the overall mass balance. The cost of the 5% polymer solution was also estimated.

The research group of Polymer Department – ICECHIM developed laboratory experiments to optimize the encapsulation conditions of the

thermotropic system in a translucent shell of water-insoluble polymer by performing the synthesis at room temperature. In this sense, a significant

number of samples were synthesized in order to accomplish the encapsulation in two variants, namely: “in situ” polymerization of vinyl/acrylic monomers dispersed in water/organic solvents and internal phase separation technique. Based on the latest version, was developed the encapsulation technology for thermotropic hydrogels comprising the following steps: achieving double emulsion water-oil-water; evaporating the solvent; decanting – washing – drying the thermotropic encapsulated system.

In this stage, at CHIMCOLOR, pilot technologies of obtaining thermochromic / thermotropic coating materials with hypsochromic / thermothropic transition in the range 25-75°C, for three primary colors (red, yellow and blue) and three types of film-forming materials, as well as for a washable paint containing a thermotropic microencapsulated system have been accomplished. All technologies have proven reproducible at pilot scale, and on this basis mass balance, specific consumption and estimated costs of the final products were estimated.

Strength, color and integrity of coating materials were tested for various media in correlation with the response to heating and reversibility of the process in successive cycles of heating-cooling for washable paints, colorless and fireproof lakes. CHIMCOLOR has drawn up a feasibility study for

the thermosensitive film-forming materials.

Results

Some original results obtained during the research were the subject of several papers published/to be published or presented as follows:

Papers

1. V. Raditoiu, A Raditoiu, L. Wagner, V. Amariutei, C.A. Nicolae, Thermochromic systems based on complexes of some triarylmethane dyes, Rev.Chim. 2013, 62(2),147-151

2. R. Ianchis, D. Donescu, R. Somoghi, M.C. Corobea, L.C. Nistor, M. Ghiurea, C. Petcu, C.A. Nicolae, R. Gabor, I. Atkinson, Miniemulsion polymerization of styrene in the presence of different commercial clays, J. Optoelectron. Adv. Mat., 2013,15 ( 5- 6), 585 – 589

3. R. Somoghi, R. Ianchis, M. Ghiurea, V. Purcar, D. Donescu, New nanostructures derived from magnetic polymer hybrids and functional silanes, J.

Optoelectron. Adv. Mat., 2013,15 ( 5- 6), 590 – 595

4. C. Boscornea, A. David, L. Ioan, M. Teodorescu, Effect of additives upon the phase transition temperature of α,ω-(2-Hydroxyethoxy)oligo(propylene oxide) in aqueous solutions, Mat.Plast, 2013,50(3), 163-166

5. V. Raditoiu, C. Radovici, A. Raditoiu, C.A. Nicolae, D.C. Culita, R.C. Fierascu, V. Amariutei, L.E. Wagner, Switching behavior of thermochromic copper and silver tetraiodomercurate embedded in silica hybrid materials, Opt. Mater., 2013, 35(12), 2565-2572

6. V. Raditoiu, A Raditoiu, V. Amariutei, C.A. Nicolae, R.A. Gabor, A. N. Frone,R. C. Fierăscu, M. Ghiurea, L.E. Wagner, G. Hubca, Silica-based hybrid coatings containing a non-ionic dye as colouring materials for cellulosic fabrics, Mat.Plast , 2013,50(4), 241-247

7. D. Donescu, R. Ianchis, C. Petcu, V. Purcar, L.C. Nistor, C. Radovici, R. Somoghi, S. F. Pop,A. Perichaut, Study of the solvents influence on the layered silicates-cation polymer hybrids properties,Digest J. of Nanomat. and Biostruct, 2013, 8 (4), 2407-2416

8. V. Purcar, S. Caprarescu, C.I. Spataru, M. Ghiurea, V. Raditoiu, C. Petcu, R. Somoghi, M.C. Corobea, D. Donescu, Preparation of hydrophobic and antireflective hybrid films by sol-gel process using perfluoroalkylsilane and tetraethoxysilane, Rev. Roum. Chim., 2013, 58 (2-3), 283-289

9. V. Purcar, O. Cinteza, D. Donescu, D. Bala, M. Ghiurea, C. Petcu, S. Caprarescu, Surface modification of silica particles assisted by CO2, J. Supercritical Fluids, 2014, 87, 34-39

10. A. Raditoiu, V.Raditoiu, V. Raditoiu, L.E.Wagner, R.A.Gabor, M.Ghiurea,C.I.Spataru, Protein Textile Fibers Coated with Silica – azo Disperse Dyes Hybrid Film-forming Materials , Mat. Plast.,2014, 51 (2), 130-132

11. A. Anghelache, M. Teodorescu, P. O. Stanescu, C. Draghici , D. M. Vuluga, Novel crosslinked thermoresponsive hydrogels with controlled poly(ethylene glycol)-poly(propylene glycol) multiblock copolymer structure, Colloid Polym. Sci.,2014, 292, 829-838

12. R. Ianchis, V.Raditoiu, L. Wagner, M. Ghiurea, R.Somoghi, C.I.Spataru , V.Purcar, L.C.Nistor , D.Donescu, Polymer Dispersions Containing Thermochromic System, Optoelectron. Adv. Mat. – R. C.,2014, 8(7-8),685-688

13. A. Raditoiu, V. Amariutei, V. Raditoiu, R. C. Fierascu, C. A. Nicolae, L. E. Wagner, Non-ionic Dyes in Silica Hybrid Materials as Coloured Coatings on Protein Fibers, Rev.Chim., 2014, 65(9),1002-1007

14. A. Raditoiu, V. Amariutei, V. Raditoiu, C. A. Nicolae, R. C. Fierascu, L.E.Wagner, Optical and thermal behavior of some colored silica hybrids deposited on polyester fabrics as coating materials, Optoelectron. Adv. Mat. – R. C.,2014, 8(9-10),862-868

15. R. Ianchis, D. Donescu, L. O. Cinteza, V. Purcar, C. L. Nistor, C. Petcu, C. A. Nicolae, R. Gabor, S. Preda, Polymer-clay nanocomposites obtained by solution polymerization of vinyl benzyl triammonium chloride in the presence of advanced functionalized clay– J. Chem.Sci., 2014,126, (3), 609-616

16. D. Donescu, R. Somoghi, C. L. Nistor, M. Ghiurea, R. Ianchis, C. Petcu, C. I. Spataru, V. Purcar, Water dispersions of silver nanoparticles stabilized by vinylethers – maleic anhydride alternating copolymers, Digest Nanomat. and Biostruct., 2014, 9, (2), 881-889

17. V. Purcar, O. Cinteza, M. Ghiurea, A. Balan, S. Caprarescu, D. Donescu Influence of hydrophobic characteristic of organo-modified precursor on wettability of silica film, Bull. Mater. Sci., 2014, 37, (1), 107-115

18. I. S. Hosu, Q. Wang, A. Vasilescu, S. F. Peteu, V. Raditoiu, S. Railian, V. Zaitsev, K. Turcheniuk, Qi Wang, M. Li, R. Boukherrouba and S. Szunerits, “Cobalt phthalocyanine tetracarboxylic acid modified reduced graphene oxide: a sensitive matrix for the electrocatalytic detection of peroxynitrite and hydrogen peroxide” , RSC Adv., 2015, 5, 1474-1484

19. R. Ianchis, I.D. Rosca, M. Ghiurea, C.I. Spataru, C.A. Nicolae, R. Gabor , V. Raditoiu, S. Preda, R.C. Fierascu , D. Donescu, “Synthesis and properties of new epoxy-organolayered silicate nanocomposites “,Applied Clay Science, 2015,103, 28–33

20. Livia Ioan, Mircea Teodorescu, Paul O. Stănescu, Constantin Drăghici, Anamaria Zaharia, Andrei Sârbu, Stefania Stoleriu, “The effect of hydrophilic bentonite nanoclay on the thermogelation properties of poly(N-isopropylacrylamide)- poly(ethylene glycol)-poly(N-isopropylacrylamide)

triblock copolymer aqueous solutions”, Journal of Macromolecular Science, Part B: Physics, 2015, 54: 316–328

21. C.Petcu, V. Purcar, A.L. Radu, R. Ianchis, E. Alexandescu, A. Sarbu, D. Ion-Ebrasu, A.R. Miron, C. Modrogan, A.I. Ciobotaru, “Removal of zinc ions from model wastewater system using bicopolymer membranes with fumed silica” Journal of Water Process Engineering 2015, 8, 1–10

Patent applications

1. Raditoiu Valentin, Wagner Luminita Eugenia, Raditoiu Alina, Amariutei Viorica,Raduly Florentina Monica, Parsu Dumitru, Parsu Lenuta, Parsu Mihai “Hydrosoluble thermochromic film forming compositions for building structures and process for obtaining them” RO Patent application A/00894/24.11.2016

2. Raditoiu Valentin, Amariutei Viorica,Wagner Luminita Eugenia, Raditoiu Alina, Raduly Florentina Monica “Microencapsulated thermochromic compositions and process for obtaining them“ RO Patent application A/00915/28.11.2016

Communications

1. R. Ianchis, A. M. Lungu, D. Donescu, C Petcu, R. Somoghi, L.C. Nistor, V. Purcar, M. Ghiurea, C. I. Spataru, Miniemulsion Polymerization Of Styrene In The Presence Of Different Layered Silicates, ICOSECS 8 – the 8-th International Conference of Chemical Societies from South – Est European Countries – “CHEMISTRY FOR THE NEW ORIZON”, Belgrad, Serbia, 27-29 june 2013.

2. R. Șomoghi, A.L. Ciripoiu, R. Ianchiș, C.L. Nistor, V. Purcar, C.I. Spataru, M. Ghiurea, C. Petcu, D. Donescu – Surface modification of Fe3O4 nanoparticles

with alkoxysilanes and the miniemulsion polymerization of the formed particles, ICOSECS 8 – the 8-th International Conference of Chemical Societies from South – Est European Countries – “CHEMISTRY FOR THE NEW HORIZON”, Belgrad, Serbia, 27-29-th june 2013.

3. C.A. Nicolae, V. Rădiţoiu, R.A. Gabor, A. Rădiţoiu – Conventional DSC and TMDSC investigation on the transitions of thermochromic pigments – 2nd Central and Eastern European Conference on Thermal Analysis and Calorimetry (CEEC-TAC2), 27–30-th august 2013, Vilnius, Lituania.

4. V. Rădiţoiu, A. Rădiţoiu, C.A. Nicolae, R.A. Gabor, M. Ghiurea, V. Amăriuţei, L.E. Wagner – Behavior of some thermochromic systems based on

spirolactone dyes embedded in epoxy resins – Romanian International Conference on Chemistry and Chemical Engineering RICCCE 18, 4-7-th september 2013, Sinaia, Romania

5. C.A. Nicolae, V. Raditoiu, A. Raditoiu, Stoichiometry of a thermochromic complex by TMDSC, 3-rd Central and Eastern European Conference on Thermal Analysis and Calorimetry (CEEC-TAC3), 25–28-th august 2015, Ljubljana, Slovenia.

6. Caprarescu Simona, Ianchis Raluca, Radu Anita-Laura, Purcar Violeta, Alexandrescu Elvira, Sarbu Andrei, Miron Alexandra Raluca, Vaireanu Danut Ionel, Cojocaru Anca, Maior Ioana, Ciobotaru Ioana Alina, Preparation, characterization and application of modified commercial organoclay polymer

membranes for removal of indigo carmine, International Symposium PRIOCHEM “Priorities of chemistry for a sustainable development”, 11-th edition, 29-30-th October 2015, Bucharest, Romania

7.Caprarescu Simona, Radu Anita-Laura ,Purcar Violeta, Petcu Cristian, Ianchis Raluca,Alexandrescu Elvira, Sarbu Andrei, Nistor Cristina Lavinia, Miron Alexandra Raluca, Ion-Ebrasu Daniela, Cojocaru Anca,Polymer membranes with plant extracts for removal of dyes from wastewaters, International Symposium PRIOCHEM “Priorities of chemistry for a sustainable development”, 11-th edition, 29-30-th October 2015, Bucharest, Romania

Contact

National Research and Development Institute for Chemistry and Petrochemistry – ICECHIM Bucharest

202 Spl. Independentei, sector 6, OP-CP 35-174, 060021, Bucharest

Project Manager: Luminita Eugenia Wagner

Tel. +40 21 316.30.62/118

Fax: +40 21 312.34.93

E-mail:

Web: www.icechim.ro

Scientific Manager: Valentin Raditoiu

Tel. +40 21 316.30.62/118

Fax: +40 21 312.34.93

E-mail:

Web: www.icechim.ro